We combine craftsmanship with advanced manufacturing technology to build injection molds that perform reliably, shot after shot. From single-cavity prototypes to multi-cavity production tools, we handle the entire tooling lifecycle.

Molds Built for Production

Quality Parts Start with Quality Tooling

Injection molding is a competitive field, and the efficiency of your tool directly impacts your bottom line. We approach mold design with a focus on cooling efficiency, smart gating, and robust ejection systems. This means you get parts out of the mold faster and with fewer defects.

We don't just cut steel; we engineer the molding process. Before a single chip is machined, we run comprehensive Moldflow analyses to predict filling patterns, identifying potential air traps or weld lines. This proactive approach saves weeks of tuning and modification later on.

Our capabilities cover the full spectrum of tooling needs. We can produce rapid aluminum tooling for market validation runs of a few thousand parts, or hardened steel production molds (P20, H13, S7) capable of running millions of cycles without missing a beat.

Optimized Cooling Cycles

We design conformal and high-efficiency cooling channels to reduce cycle times, allowing you to produce more parts per hour.

Comprehensive DFM

Detailed Design for Manufacturability feedback helps you adjust part geometry for better molding results and lower tooling costs.

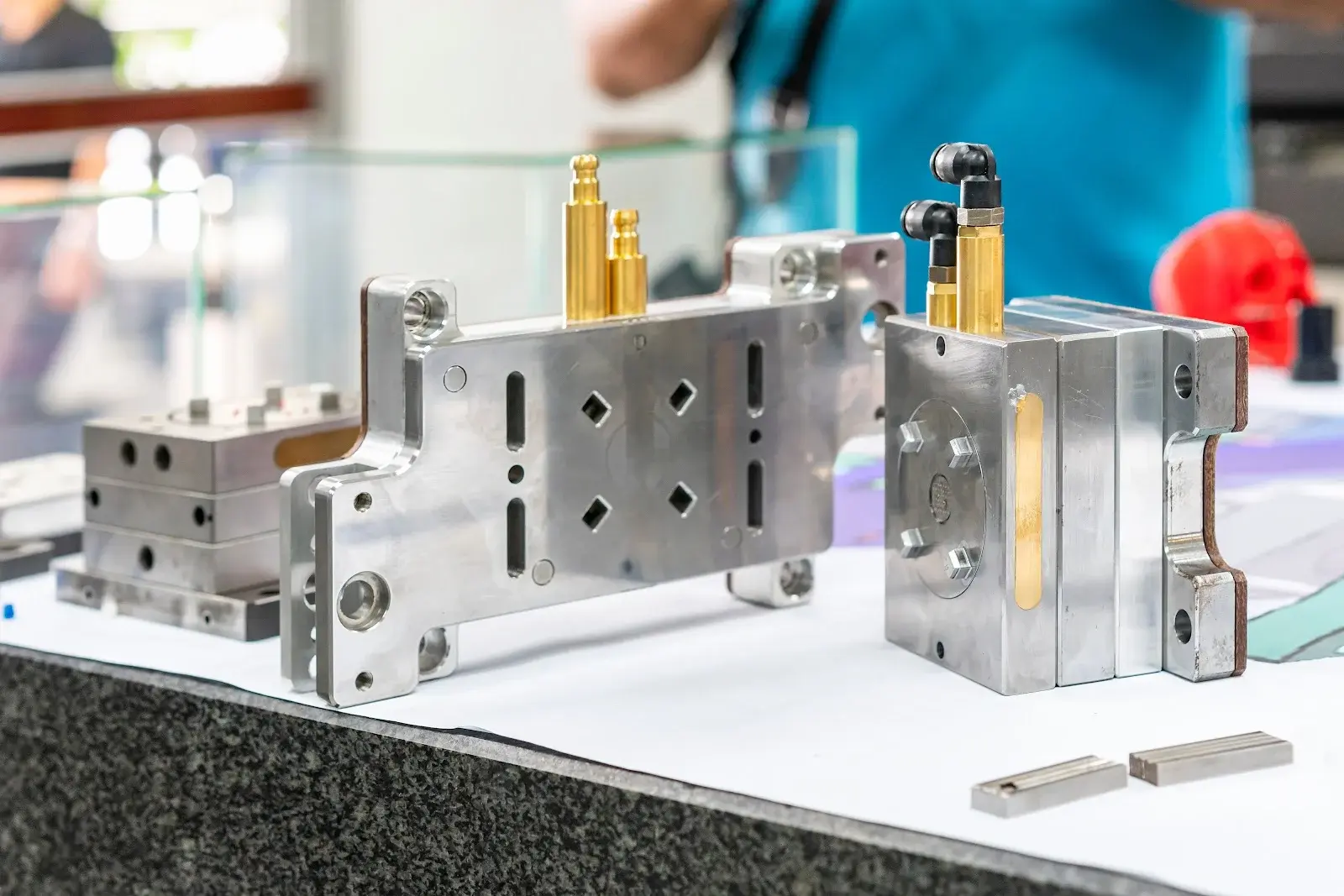

Precision Machining

Utilizing high-speed CNC and EDM (Electrical Discharge Machining) to achieve intricate details and superior surface finishes.

Tool Life Management

We select the right steel grades and coatings based on your production volume and financing goals, ensuring you don't overpay for unnecessary durability or underprepare for high volumes.

Our Services

R&D

Transforming ideas into groundbreaking solutions through advanced research, prototyping, and process optimization.

Product Development

From ideation to market-ready products, we design functional, visually appealing, and efficient products.

Injection Molds

Precision engineering for high-quality injection molded parts.

CNC Service

High-precision CNC machining services for complex parts.

3D Printing

Advanced 3D printing technology for rapid prototyping and custom production.

Our Projects

Comprehensive solutions tailored to meet your needs with excellence and precision.

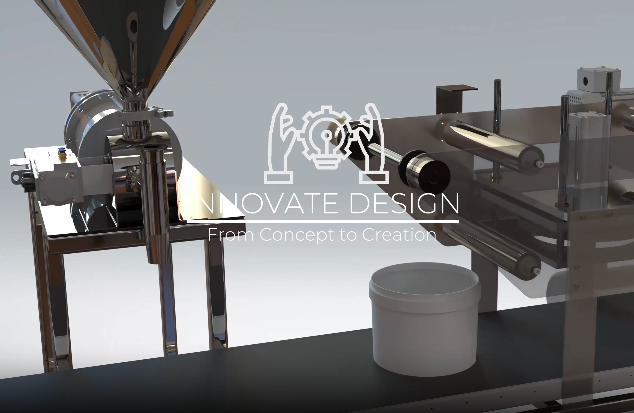

Project 1 - packaging machine

Driving innovation through research and development tailored to your needs.

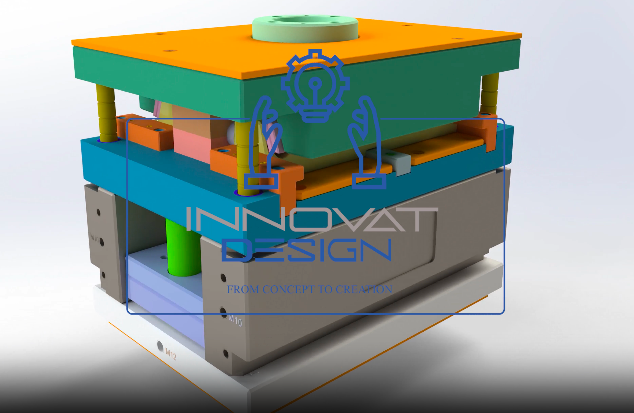

Project 2 - injection mold

Transforming ideas into tangible products with precision and expertise.

Project 3 - spare parts

Providing cutting-edge CNC machining solutions for high precision projects.

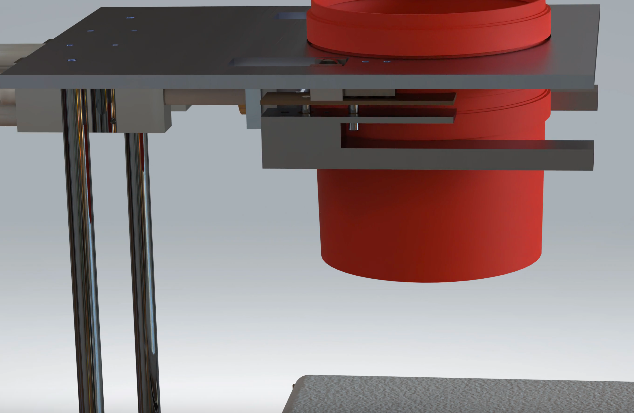

Project 4 - R&D

Designing and manufacturing high-quality injection molds for various applications.

Achievements

Why Trust Us with Your Tooling?

We understand that a mold is a significant investment. We treat it with the seriousness it deserves, prioritizing communication and transparency.

Engineering First

Designed for Reality

We aren't just toolmakers; we are engineers. We understand part function and can suggest tweaks that make molding easier without compromising your design intent.

Transparent Timelines

No Surprises

Tooling programs are often on the critical path. We provide realistic schedules and regular photo/video updates during the machining process.

Global Standards

Quality You Can Measure

Whether it's DME or HASCO standards, we build tools that fit seamlessly into your local injection molding machines and supply chain.

Get a Quote for Your Injection Mold

Contact Our Tooling TeamFrom Print to Part

Our structured process ensures that we catch potential issues early and deliver a tool that works right out of the box.

Design Review & DFM

We analyze your 3D CAD data, identifying draft angle issues, thick sections, or undercuts that need attention.

Mold Design

Our designers create a full 3D assembly of the mold, including cooling lines and ejection, which you review and approve.

Machining & Assembly

We cut the steel using high-precision CNCs and assemble the components, fitting everything with tight tolerances.

T1 Sampling & Validation

We run the first shots (T1) and send you samples along with a dimensional inspection report for your approval.

Frequently Asked Questions

Everything you need to know about our services. Can’t find the answer you’re looking for? Feel free to contact us.

Get in Touch

Have questions or want to discuss a project? We love to hear from you. Fill out the form below and we ll get back to you within 24 hours.

Phone

+972598486982Monday - Saturday:8:00 AM to 6:00 PM

Sunday:Closed