Transform your innovative ideas into production-ready products with our comprehensive product development for manufacturing services. We bridge the gap between concept and production, delivering engineered solutions optimized for manufacturability, quality, cost-efficiency, and market success across all industries.

Product Development for Manufacturing Excellence

From Concept to Production-Ready Products

We understand that successful product development for manufacturing requires more than great design—it demands deep understanding of production processes, materials, costs, and quality requirements. Our integrated approach ensures every product we develop is engineered for efficient, cost-effective manufacturing while meeting all functional, aesthetic, and regulatory requirements.

Whether you're a startup bringing a revolutionary concept to market or an established company expanding your product line, our product development for manufacturing services provide the expertise you need. We guide you through every stage—from initial ideation and concept development through detailed engineering, prototyping, testing, and production launch.

Our dedicated team leverages advanced CAD/CAE tools, rapid prototyping technologies, and deep manufacturing partnerships to accelerate your product development timeline while minimizing risk. We don't just design products; we engineer complete manufacturing solutions that deliver competitive advantage and market success.

End-to-End Product Development

Complete product development for manufacturing services from initial concept, industrial design, and engineering through prototyping, testing, and production transfer—all under one roof.

Design for Manufacturing (DFM)

Every product we develop is optimized for manufacturability from the start, reducing production costs, minimizing defects, and accelerating time-to-market.

Multidisciplinary Expertise

Our team combines industrial designers, mechanical engineers, electrical engineers, materials scientists, and manufacturing specialists for comprehensive product development.

Rapid Prototyping & Validation

Advanced prototyping capabilities including 3D printing, CNC machining, and soft tooling enable fast iteration and thorough validation before committing to production tooling.

Manufacturing Partnerships

Established relationships with certified manufacturers worldwide ensure seamless transition from product development to volume production across all manufacturing processes.

Quality & Compliance

Rigorous quality engineering throughout product development ensures your products meet industry standards, regulatory requirements, and customer expectations.

Our Services

R&D

Transforming ideas into groundbreaking solutions through advanced research, prototyping, and process optimization.

Product Development

From ideation to market-ready products, we design functional, visually appealing, and efficient products.

Injection Molds

Precision engineering for high-quality injection molded parts.

CNC Service

High-precision CNC machining services for complex parts.

3D Printing

Advanced 3D printing technology for rapid prototyping and custom production.

Our Projects

Comprehensive solutions tailored to meet your needs with excellence and precision.

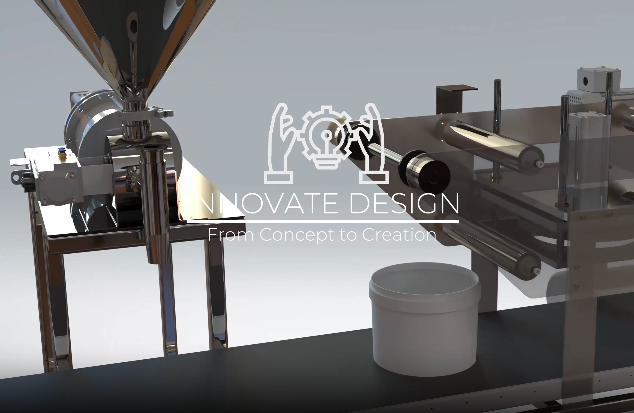

Project 1 - packaging machine

Driving innovation through research and development tailored to your needs.

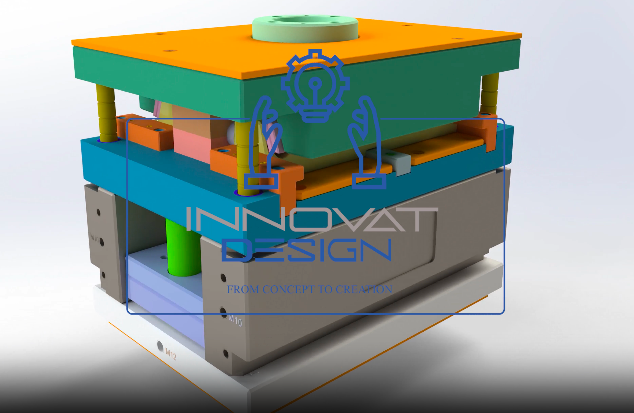

Project 2 - injection mold

Transforming ideas into tangible products with precision and expertise.

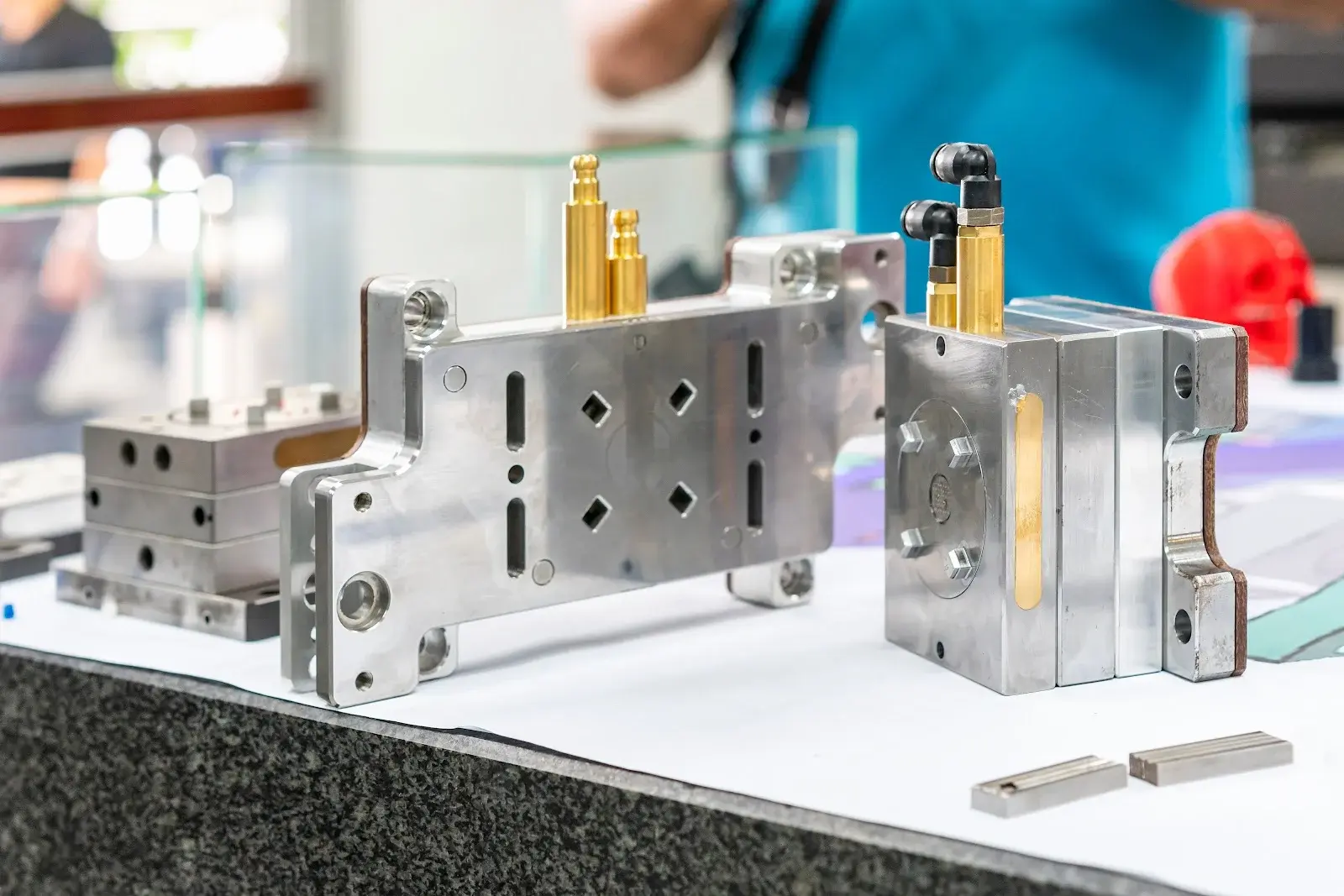

Project 3 - spare parts

Providing cutting-edge CNC machining solutions for high precision projects.

Project 4 - R&D

Designing and manufacturing high-quality injection molds for various applications.

Achievements

Why Choose Us for Product Development for Manufacturing?

We are committed to delivering product development for manufacturing solutions that accelerate your path from concept to market success. With 500+ products developed and launched, our track record demonstrates our expertise in creating manufacturable, market-winning products.

Manufacturing-First Approach

Designed for Production

Our product development for manufacturing philosophy embeds manufacturability into every design decision, ensuring products that are efficient and economical to produce.

Proven Development Process

Risk-Mitigated Innovation

Our structured product development for manufacturing methodology systematically reduces risk while maximizing innovation, ensuring successful product launches.

- Stage-Gate Development Process

- Early Risk Identification & Mitigation

- Iterative Prototyping & Validation

- Comprehensive Design Reviews

Complete Partnership

Your Extended Product Team

We become an extension of your organization, providing dedicated resources, transparent communication, and committed partnership throughout your product development journey.

- Dedicated Project Management

- Regular Progress Updates & Reviews

- Collaborative Decision Making

- Long-Term Product Support

Ready to Start Your Product Development for Manufacturing Project?

Contact Us NowEnabling Product Success Through Manufacturing Excellence

Our mission is to empower innovators and businesses with world-class product development for manufacturing services that transform ideas into successful, market-leading products. We are committed to engineering excellence, manufacturing innovation, and building partnerships that drive growth and competitive advantage for our clients worldwide.

Transforming Ideas into Manufacturable Products

Accelerating Time-to-Market for New Products

Optimizing Products for Cost-Effective Manufacturing

Ensuring Quality and Regulatory Compliance

Building Long-Term Product Development Partnerships

Our Product Development for Manufacturing Process

A proven, systematic workflow designed to transform your ideas into successful, production-ready products efficiently while minimizing risk and maximizing market potential.

Discovery & Strategy

We begin by understanding your vision, market requirements, target users, and business objectives. We define product specifications, identify manufacturing constraints, and develop a comprehensive product development roadmap.

Concept Design & Engineering

Our designers and engineers create innovative concepts, develop detailed 3D CAD models, perform engineering analysis, and apply Design for Manufacturing (DFM) principles to ensure producibility from the start.

Prototyping & Validation

We build functional prototypes using rapid prototyping technologies, conduct rigorous testing for performance, durability, and user experience, and iterate designs based on real-world validation results.

Design for Manufacturing Optimization

We optimize final designs for your chosen manufacturing processes, finalize material selections, complete tolerance analysis, and prepare comprehensive manufacturing documentation and specifications.

Production Transfer & Launch

We manage tooling development, oversee first article production, validate manufacturing quality, and support your product launch to ensure successful transition from development to volume manufacturing.

Frequently Asked Questions

Everything you need to know about our services. Can’t find the answer you’re looking for? Feel free to contact us.

Get in Touch

Have questions or want to discuss a project? We love to hear from you. Fill out the form below and we ll get back to you within 24 hours.

Phone

+972598486982Monday - Saturday:8:00 AM to 6:00 PM

Sunday:Closed