3D Printing

Rapid Prototyping

Quick turnaround for concept validation and testing.

01

Versatile Materials

From plastics to resins and metals, we offer multiple printing options.

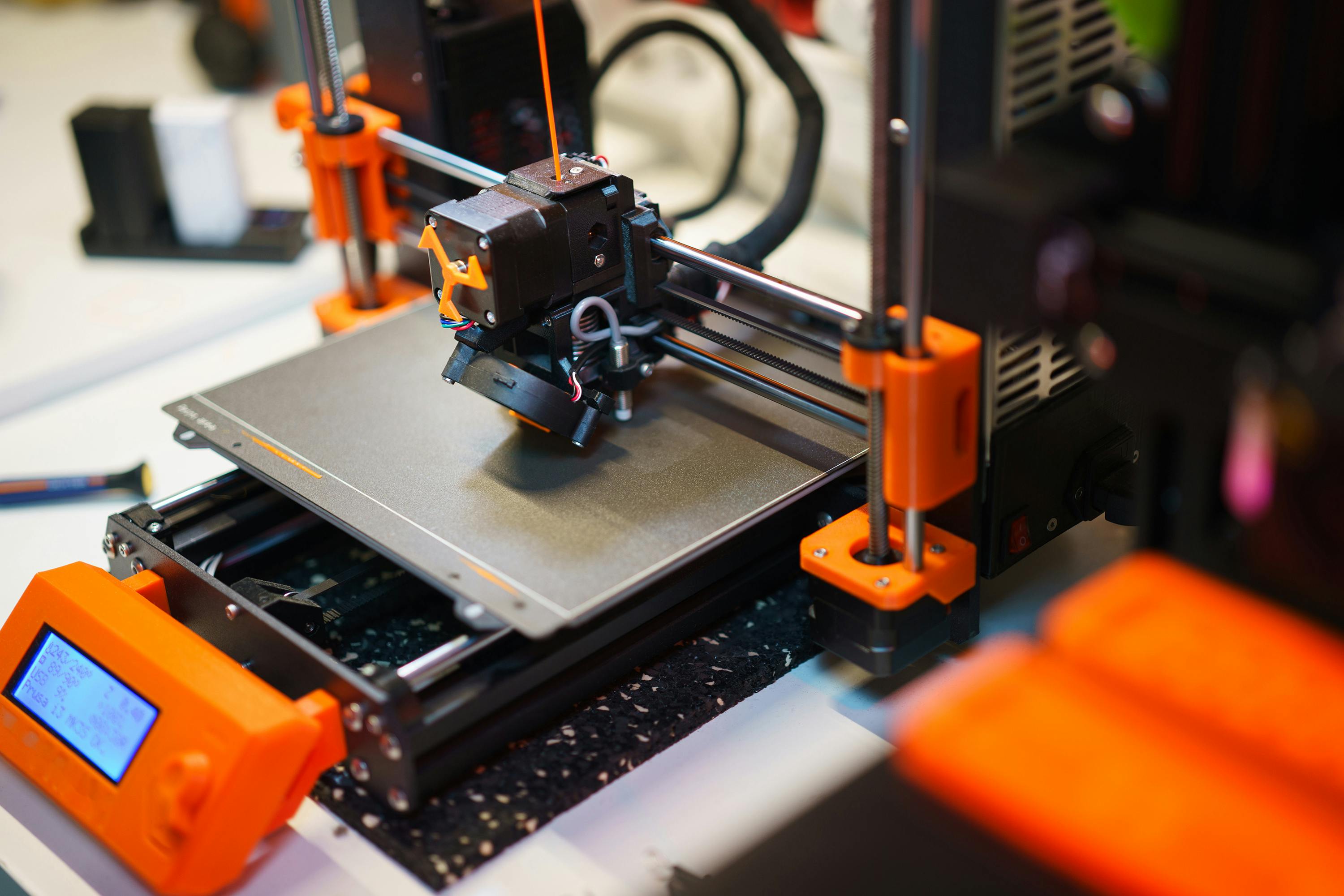

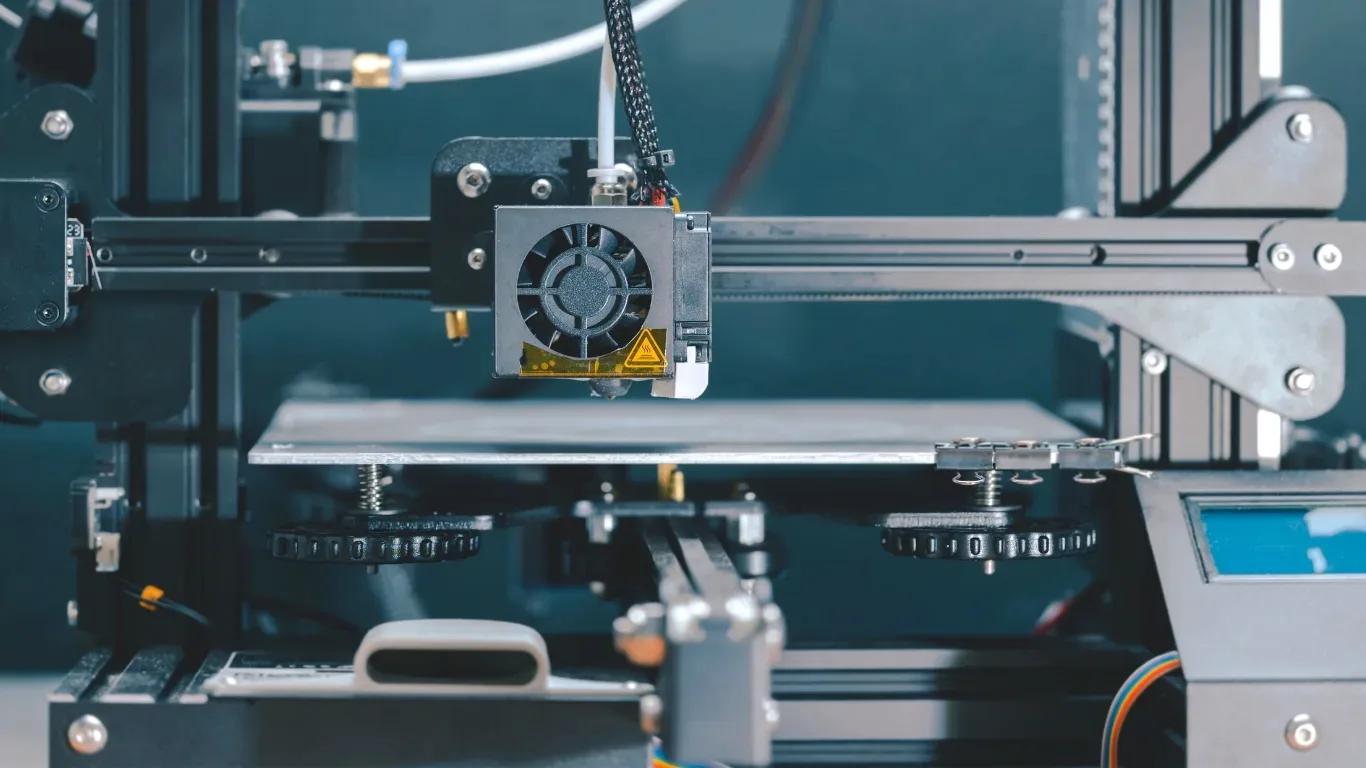

02What is 3D Printing?

An additive manufacturing process that builds parts layer by layer using digital 3D models. The technology enables rapid prototyping and production of complex geometries that would be difficult or impossible with traditional methods. Materials range from standard plastics to advanced composites, metals and bio-compatible materials.

Technologies We Use

We employ industry-leading FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering) technologies. Our advanced printer fleet enables high-resolution prototypes, functional parts, and small-batch production runs with precise tolerances and excellent surface finish across a wide range of materials.

Design Optimization

We help refine your CAD models for optimal 3D printing results through topology optimization, part orientation analysis, support structure planning, and layer thickness adjustments. Our engineering team ensures designs maximize strength while minimizing material usage and print time for cost-effective production.

Surface Finishes

Choose from a wide range of professional finishing options including basic, sanded, vapor smoothed, polished, painted, or metallic coatings. Our post-processing techniques ensure optimal aesthetics and functionality while meeting specific surface roughness requirements for your application.

Applications

Ideal for custom parts, small-batch production, and rapid prototyping. Our 3D printing solutions enable quick iteration of designs, validation of form and fit, and production of end-use parts. Perfect for industries requiring specialized components, customized tooling, or complex geometries with fast turnaround times.