Deliver high-quality plastic parts at scale with our comprehensive plastic injection molding services. From initial concept and mold design to full-scale production, we provide end-to-end injection molding solutions that combine engineering excellence, advanced tooling, and manufacturing precision for industries worldwide.

Plastic Injection Molding Expertise

From Concept to Million-Part Production

We understand the intricacies of plastic injection molding and what it takes to produce flawless parts consistently. Our process encompasses detailed mold flow analysis, precision tooling design, optimized process parameters, and rigorous quality control to ensure every injection molded part meets exact dimensional and aesthetic specifications. We don't just manufacture parts; we engineer complete injection molding solutions.

Whether you require low-volume prototype injection molding for product validation or high-volume production runs of millions of parts, we have the specialized capabilities to deliver. Our multidisciplinary approach covers everything from resin selection and part design optimization to mold engineering, process development, and secondary operations like assembly and finishing.

Our dedicated team leverages state-of-the-art injection molding machines, scientific molding principles, and real-time process monitoring to ensure consistent quality across every production run. We partner with you as a strategic manufacturing ally, providing transparent communication, on-time delivery, and competitive pricing that drives your business success.

Full-Service Injection Molding

Complete plastic injection molding services from part design consultation and mold engineering through production, assembly, and fulfillment—all under one roof.

Advanced Molding Technology

State-of-the-art injection molding machines from 50 to 1,500 tons, equipped with robotics, scientific molding controls, and real-time quality monitoring systems.

Expert Mold Engineering

In-house mold design team utilizing Moldflow simulation, precision CNC machining, and EDM to build production-grade injection molds with exceptional longevity.

Rapid Turnaround

Prototype injection molding in as little as 2 weeks. Production tooling in 4-8 weeks. We accelerate your time-to-market without sacrificing quality.

Material Versatility

Expertise in molding all thermoplastics including ABS, Polycarbonate, Nylon, Acetal, Polypropylene, TPE, and high-performance resins like PEEK and Ultem.

Quality Assurance

ISO 9001:2015 certified facility with comprehensive inspection capabilities including CMM, optical measurement, and statistical process control (SPC).

השירותים שלנו

מחקר ופיתוח

הפיכת רעיונות לפתרונות פורצי דרך באמצעות מחקר מתקדם, אב-טיפוס ואופטימיזציה של תהליכים.

פיתוח מוצר

מרעיון למוצרים מוכנים לשוק, אנו מעצבים מוצרים פונקציונליים, אסתטיים ויעילים.

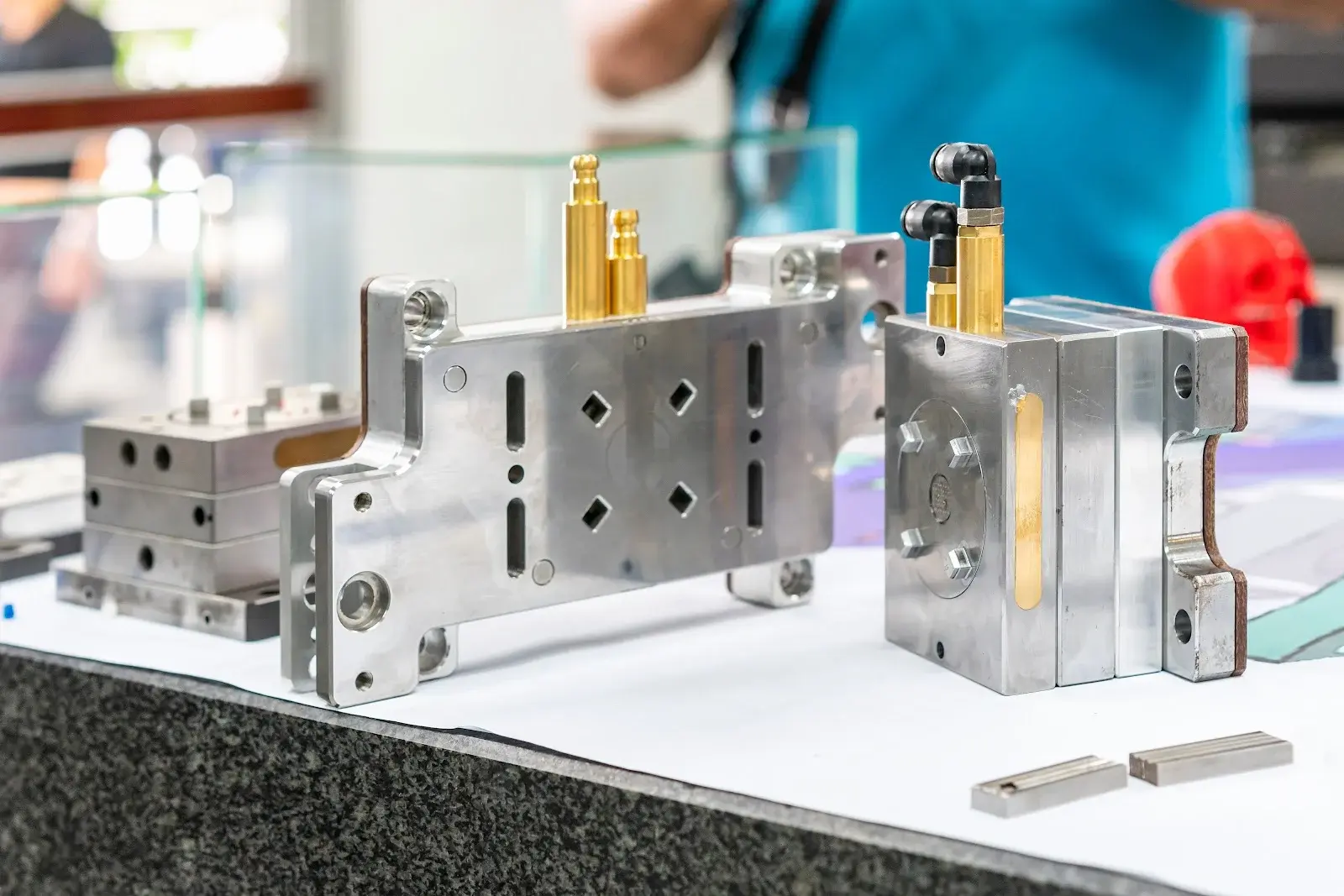

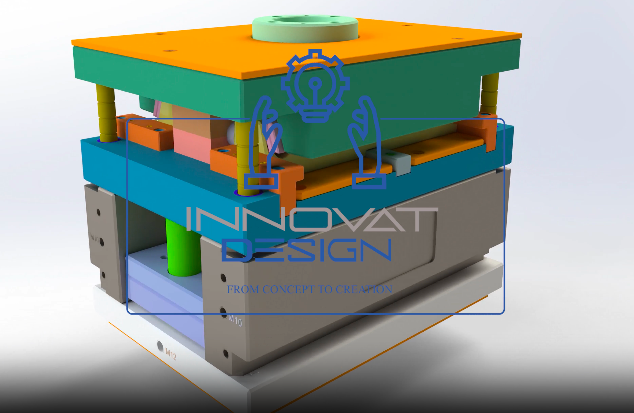

תבניות הזרקה

הנדסה מדויקת לחלקים מוזרקים באיכות גבוהה.

שירות CNC

שירותי עיבוד שבבי CNC בדיוק גבוה לחלקים מורכבים.

הדפסת תלת מימד

טכנולוגיית הדפסה תלת-ממדית מתקדמת לאב-טיפוס מהיר וייצור מותאם אישית.

השירותים שלנו

גלה את מגוון הפתרונות התעשייתיים שלנו

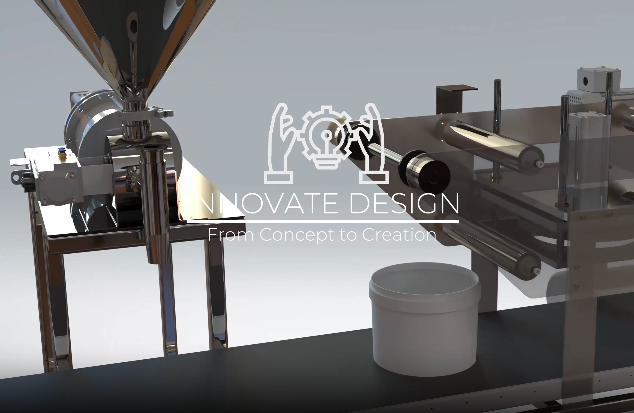

מכונת אריזה

פתרונות אריזה אוטומטיים מתקדמים לתעשיות שונות.

תבניות הזרקה

תבניות הזרקה מדויקות לייצור רכיבי פלסטיק.

חלקי חילוף

מלאי מקיף של חלקי חילוף מקוריים ותחליפיים.

מחקר ופיתוח

מחקר ופיתוח מתקדם לפתרונות תעשייתיים של הדור הבא.

Achievements

Why Choose Our Plastic Injection Molding Services?

We are committed to delivering plastic injection molding solutions that exceed expectations in quality, precision, and value. With 500+ successful projects and millions of parts produced, our track record speaks for itself.

Injection Molding Innovation

Cutting-Edge Solutions

We push the boundaries of plastic injection molding with advanced techniques like scientific molding, multi-shot molding, insert molding, and micro-molding.

Precision & Consistency

Every Part, Every Time

We maintain exceptional precision in every injection molded part, achieving tolerances as tight as ±0.025mm with Cpk values exceeding 1.33.

- Tight Tolerance Injection Molding (±0.025mm)

- Scientific Molding Process Control

- In-Process SPC Monitoring

- 100% Part Inspection Available

True Manufacturing Partnership

Your Success Is Our Priority

We go beyond being a vendor—we become your plastic injection molding partner, invested in your product's success from development through ongoing production.

- Dedicated Project Management

- Design for Injection Molding (DFM) Support

- Flexible Production Scheduling

- Vendor-Managed Inventory (VMI) Programs

Ready to Start Your Plastic Injection Molding Project?

Contact Us NowShaping the Future of Plastic Injection Molding

Our mission is to empower businesses with world-class plastic injection molding solutions that transform ideas into high-quality products. We are committed to manufacturing excellence, continuous innovation, and building lasting partnerships that drive mutual success. Every injection molded part we produce reflects our dedication to precision, quality, and customer satisfaction.

Delivering Precision Injection Molded Parts Globally

Advancing Sustainable Plastic Manufacturing Practices

Investing in Cutting-Edge Injection Molding Technology

Building Long-Term Customer Partnerships

Maintaining the Highest Standards of Quality & Safety

Our Plastic Injection Molding Process

A proven, streamlined workflow designed to take your project from initial concept to production-ready injection molded parts efficiently and effectively.

Consultation & DFM Review

We begin by understanding your requirements, reviewing your part design, and providing a comprehensive Design for Injection Molding (DFM) analysis with recommendations to optimize moldability, quality, and cost.

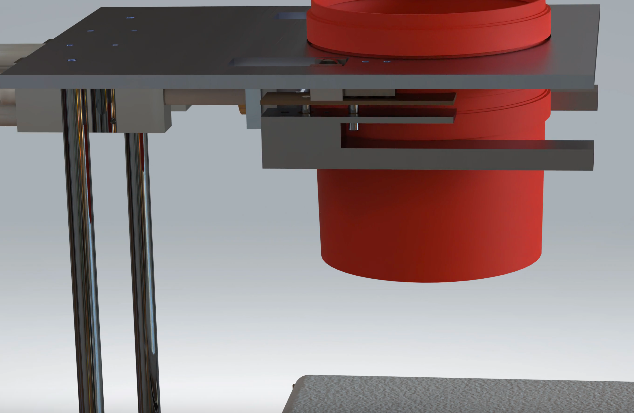

Mold Design & Simulation

Our engineers design precision injection molds using advanced CAD software and validate designs with Moldflow simulation to optimize gate locations, cooling, and eliminate potential defects before steel is cut.

Tooling Fabrication

We manufacture injection molds using CNC machining, EDM, and precision grinding. Every mold undergoes rigorous inspection and dimensional verification before sampling begins.

Sampling & Process Development

We conduct T1, T2 sampling trials, fine-tune injection molding parameters using scientific molding principles, and submit samples with complete FAI documentation for your approval.

Production & Quality Control

Upon approval, we ramp into full production with real-time process monitoring, in-process inspections, and comprehensive quality documentation. Parts are packed and shipped to your specifications.

Frequently Asked Questions

Everything you need to know about our services. Can’t find the answer you’re looking for? Feel free to contact us.

צור קשר

יש לך שאלות או רוצה לדבר על פרויקט? אנחנו אוהבים לשמוע ממך. מלא את הטופס למטה ונחזור אליך תוך 24 שעות.

דוא"ל

[email protected]טלפון

+972598486982ראשון - חמישי:8:00 עד 18:00

שישי:סגור