Manufacture high-quality injection moulding machine products with precision, consistency, and efficiency. From simple components to complex assemblies, our advanced injection moulding machines and expert engineering team deliver superior plastic products for automotive, medical, electronics, consumer goods, and industrial applications worldwide.

Injection Moulding Machine Products Excellence

Precision Plastic Products at Scale

We understand what it takes to manufacture exceptional injection moulding machine products. Our facility houses a comprehensive range of injection moulding machines from 50 to 2,000 tons, enabling us to produce plastic products ranging from micro-components weighing fractions of a gram to large structural parts. Every product we manufacture reflects our commitment to precision, quality, and consistency.

Whether you need high-volume injection moulding machine products for automotive applications, precision medical-grade components, intricate electronic housings, or durable industrial parts, we have the expertise and equipment to deliver. Our vertically integrated capabilities include mould design, tooling fabrication, injection moulding production, secondary operations, and complete assembly services.

Our dedicated team leverages scientific moulding principles, advanced process monitoring, and comprehensive quality systems to ensure every injection moulding machine product meets your specifications. We invest continuously in the latest injection moulding machine technology, automation, and inspection equipment to deliver products that exceed expectations while maintaining competitive pricing.

Advanced Injection Moulding Machines

Our facility features 50+ injection moulding machines ranging from 50 to 2,000 tons, including servo-hydraulic, all-electric, and two-shot moulding capabilities for diverse product requirements.

Diverse Product Capabilities

We manufacture injection moulding machine products of all types—from micro-moulded components to large structural parts, thin-wall packaging to thick-wall industrial products.

Precision Tooling

In-house mould design and fabrication ensures our injection moulding machine products achieve tight tolerances (±0.025mm) with exceptional consistency across millions of parts.

Rapid Production

Optimized cycle times and 24/7 production capability enable fast turnaround on injection moulding machine products—from prototype quantities to millions of units.

Material Expertise

We process 100+ thermoplastic materials including commodity resins, engineering plastics, and high-performance polymers to create injection moulding products for any application.

Complete Quality Assurance

ISO 9001:2015 certified with comprehensive inspection capabilities including CMM, optical measurement, and real-time SPC monitoring for all injection moulding machine products.

Our Services

R&D

Transforming ideas into groundbreaking solutions through advanced research, prototyping, and process optimization.

Product Development

From ideation to market-ready products, we design functional, visually appealing, and efficient products.

Injection Molds

Precision engineering for high-quality injection molded parts.

CNC Service

High-precision CNC machining services for complex parts.

3D Printing

Advanced 3D printing technology for rapid prototyping and custom production.

Our Projects

Comprehensive solutions tailored to meet your needs with excellence and precision.

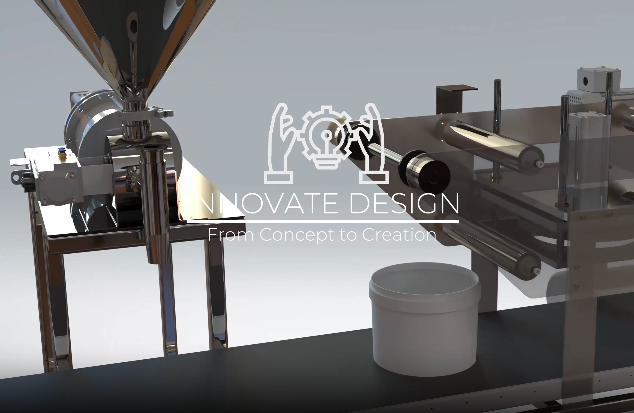

Project 1 - packaging machine

Driving innovation through research and development tailored to your needs.

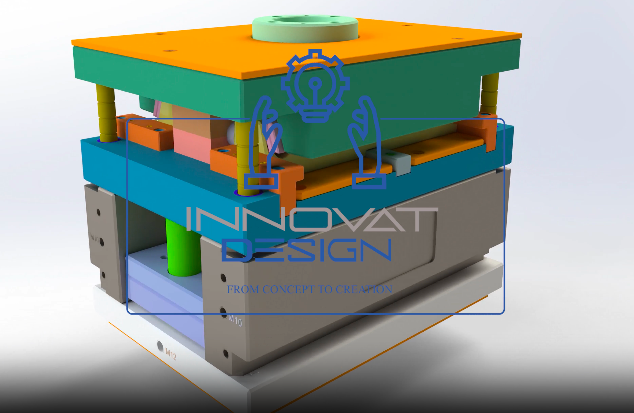

Project 2 - injection mold

Transforming ideas into tangible products with precision and expertise.

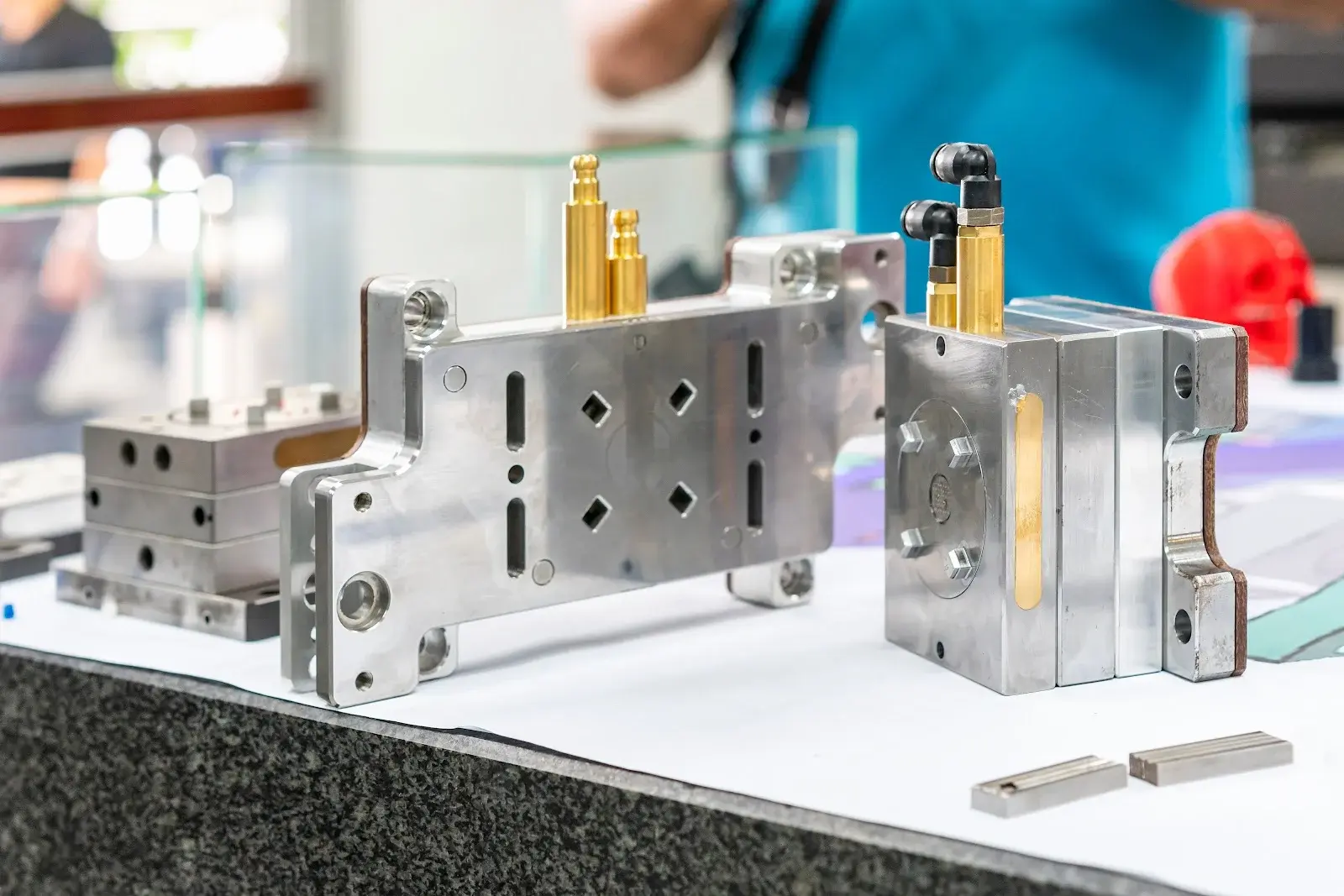

Project 3 - spare parts

Providing cutting-edge CNC machining solutions for high precision projects.

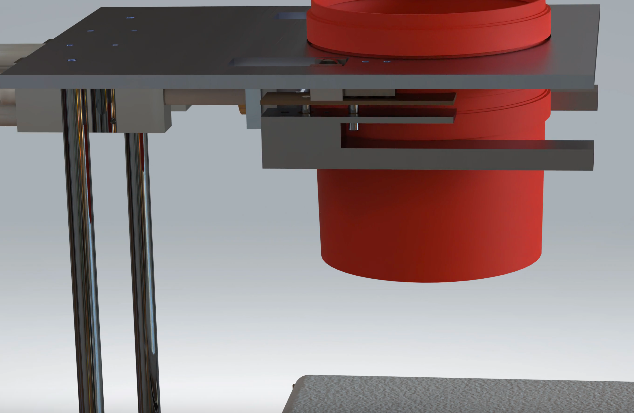

Project 4 - R&D

Designing and manufacturing high-quality injection molds for various applications.

Achievements

Why Choose Us for Injection Moulding Machine Products?

We are committed to manufacturing injection moulding machine products that exceed quality expectations while delivering exceptional value. With 20+ years of experience, 500+ active moulds, and millions of products shipped annually, we are your trusted injection moulding partner.

Product Innovation

Engineering Excellence

We help you develop superior injection moulding machine products through innovative design, advanced materials, and cutting-edge manufacturing techniques.

Consistent Quality

Zero-Defect Manufacturing

Every injection moulding machine product we manufacture meets rigorous quality standards through scientific moulding, process control, and comprehensive inspection.

- Scientific Moulding Process Control

- Real-Time SPC Monitoring

- Automated Vision Inspection

- Full Dimensional Verification (CMM)

Reliable Partnership

Your Manufacturing Ally

We become an extension of your team, providing responsive service, transparent communication, and flexible solutions for all your injection moulding machine product needs.

- Dedicated Account Management

- Flexible Production Scheduling

- Kanban & VMI Programs

- Global Logistics Support

Ready to Manufacture Your Injection Moulding Machine Products?

Contact Us NowManufacturing World-Class Injection Moulding Machine Products

Our mission is to be the global leader in injection moulding machine products manufacturing, delivering exceptional quality, innovation, and value to customers worldwide. We are committed to continuous improvement, sustainable manufacturing practices, and building lasting partnerships that drive mutual success through superior plastic products.

Delivering Superior Injection Moulding Machine Products Globally

Investing in Advanced Injection Moulding Machine Technology

Maintaining Zero-Defect Quality Standards

Promoting Sustainable Plastic Manufacturing Practices

Building Long-Term Customer Partnerships

Our Injection Moulding Machine Products Process

A streamlined, proven workflow designed to deliver high-quality injection moulding machine products from initial concept through ongoing production and fulfillment.

Product Consultation & DFM

We review your injection moulding machine product requirements, analyse part designs for manufacturability, and provide detailed DFM recommendations to optimize quality, cost, and production efficiency.

Mould Design & Fabrication

Our tooling engineers design precision moulds optimized for your injection moulding machine products, validated through mould flow simulation. We fabricate moulds in-house or through certified partners.

Process Development & Sampling

We develop optimized injection moulding machine parameters using scientific moulding principles, produce sample products for your approval, and complete comprehensive first article inspection (FAI).

Production & Quality Control

Upon approval, we commence full production of your injection moulding machine products with real-time process monitoring, in-process inspection, and rigorous quality control at every stage.

Secondary Operations & Fulfillment

We provide complete secondary services including assembly, printing, painting, and packaging. Your injection moulding machine products are delivered on time to your specifications worldwide.

Frequently Asked Questions

Everything you need to know about our services. Can’t find the answer you’re looking for? Feel free to contact us.

Get in Touch

Have questions or want to discuss a project? We love to hear from you. Fill out the form below and we ll get back to you within 24 hours.

Phone

+972598486982Monday - Saturday:8:00 AM to 6:00 PM

Sunday:Closed