Transform your product concepts into production-ready plastic parts with our comprehensive plastic molding design services. We specialize in injection mold engineering, precision tooling design, and end-to-end manufacturing support for thermoplastic and thermoset applications across all industries.

Plastic Molding Excellence

From Design to Mass Production

We understand the complexities of plastic molding and injection mold design. Our process involves rigorous mold flow analysis, detailed 3D cavity modeling, and iterative design refinement to ensure your plastic parts meet all dimensional, aesthetic, and functional requirements. We don't just design molds; we engineer for optimal cycle times, minimal defects, and maximum tool longevity.

Whether you need single-cavity prototype molds for validation or multi-cavity production molds for high-volume manufacturing, we have the specialized expertise to deliver. Our multidisciplinary approach covers everything from plastic material selection and gate design to cooling channel optimization and ejection system engineering.

Our committed team leverages state-of-the-art mold flow simulation software and DFM principles to reduce time-to-market while maintaining the highest standards of tooling quality. We partner with trusted mold makers worldwide to ensure your injection molds are built to exact specifications, delivering consistent, high-quality plastic parts every cycle.

Expert Mold Engineers

Access a team of highly skilled plastic molding engineers with 15+ years of experience across automotive, medical, consumer electronics, and packaging industries.

Advanced Mold Flow Analysis

We utilize Moldflow, Moldex3D, and SolidWorks Plastics to simulate fill patterns, predict defects, and optimize gate locations before cutting steel.

Cost-Optimized Tooling

Our mold designs are optimized for manufacturability, reducing tooling costs by up to 30% through smart cavity layouts and efficient cooling designs.

Fast Turnaround

Rapid prototype molds in 2-3 weeks. Production-grade tooling in 6-8 weeks. We meet your launch deadlines without compromising quality.

Material Expertise

Deep knowledge of thermoplastics (ABS, PC, PP, PA, POM, PEEK) and thermosets, ensuring optimal material selection for your application.

Global Manufacturing Support

We coordinate with certified mold makers in USA, Europe, and Asia to deliver quality tooling at competitive prices with full documentation.

Our Services

R&D

Transforming ideas into groundbreaking solutions through advanced research, prototyping, and process optimization.

Product Development

From ideation to market-ready products, we design functional, visually appealing, and efficient products.

Injection Molds

Precision engineering for high-quality injection molded parts.

CNC Service

High-precision CNC machining services for complex parts.

3D Printing

Advanced 3D printing technology for rapid prototyping and custom production.

Our Projects

Comprehensive solutions tailored to meet your needs with excellence and precision.

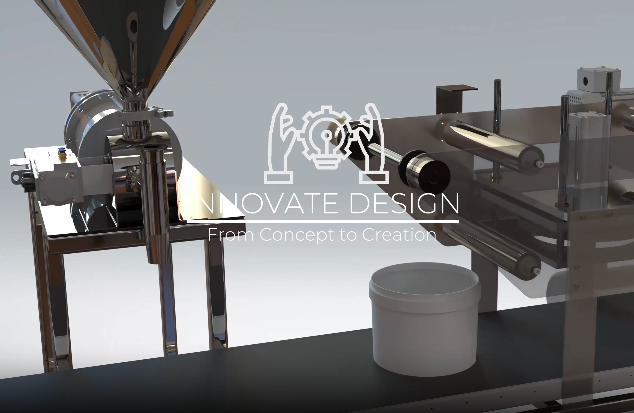

Project 1 - packaging machine

Driving innovation through research and development tailored to your needs.

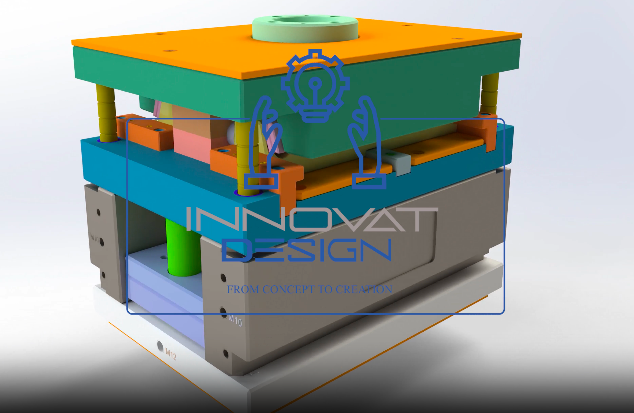

Project 2 - injection mold

Transforming ideas into tangible products with precision and expertise.

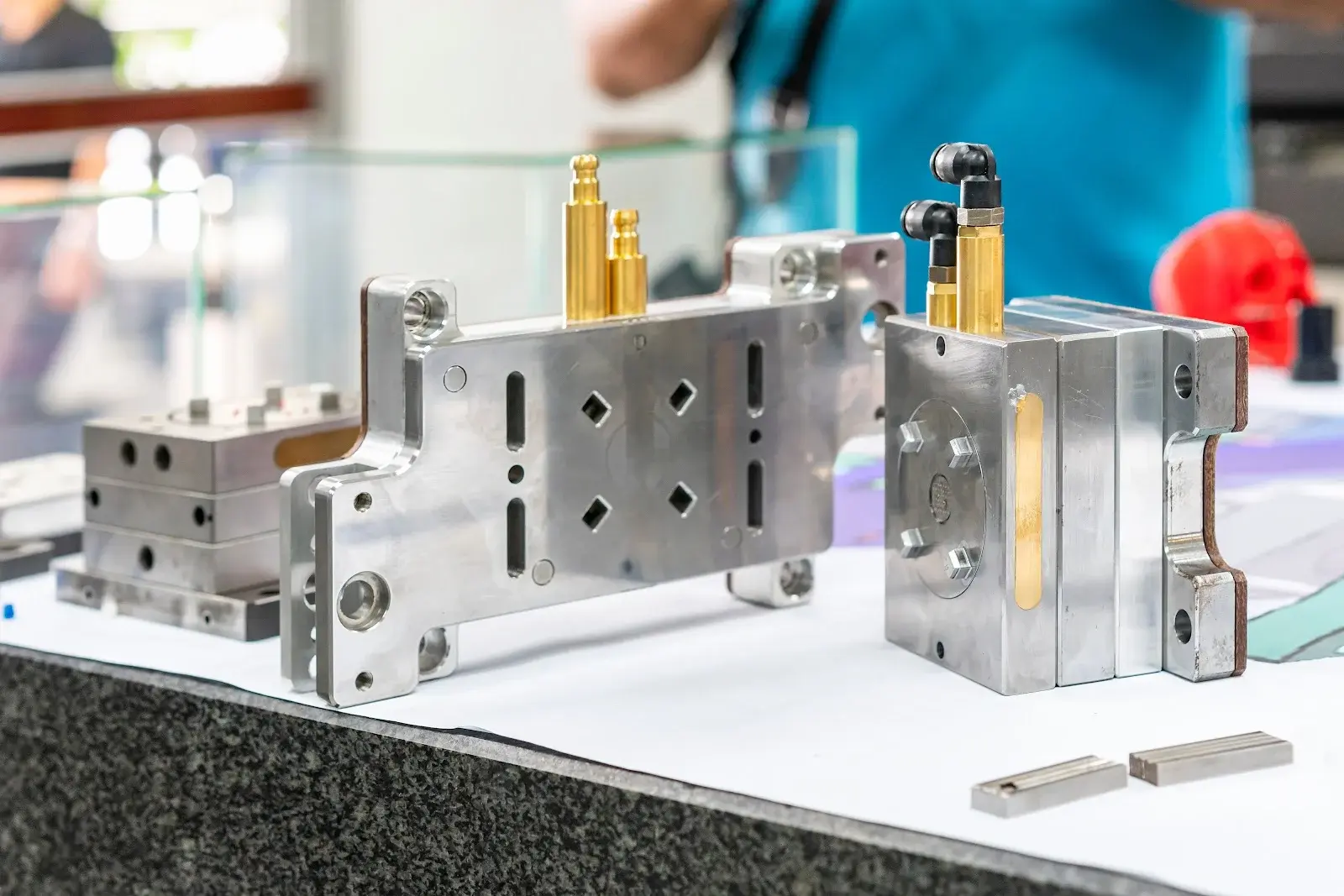

Project 3 - spare parts

Providing cutting-edge CNC machining solutions for high precision projects.

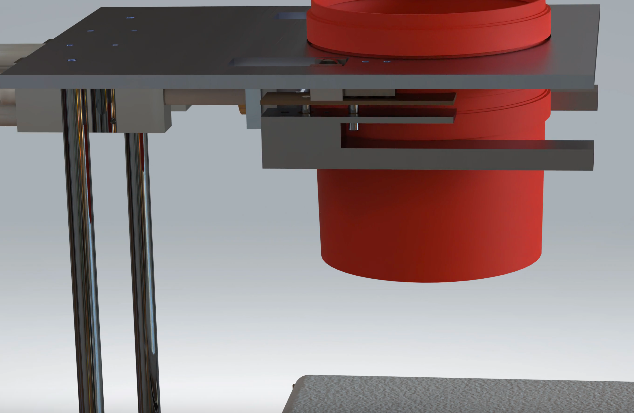

Project 4 - R&D

Designing and manufacturing high-quality injection molds for various applications.

Achievements

Why Choose Our Plastic Molding Services?

We are committed to delivering plastic molding solutions that reduce costs, accelerate production, and ensure consistent part quality. Our track record includes 500+ successful mold projects across diverse industries.

Molding Innovation

Advanced Design Solutions

We solve complex plastic molding challenges using innovative approaches like conformal cooling, hot runner systems, and multi-shot molding.

Precision Tooling

Micron-Level Accuracy

We maintain the highest standards of mold precision, achieving tolerances as tight as ±0.01mm for critical plastic components.

- Tight Tolerance Mold Design (±0.01mm)

- Comprehensive Mold Flow Simulation

- First Article Inspection (FAI) Support

- Tool Qualification & Validation Reports

End-to-End Partnership

From Concept to Production

We support you through the entire plastic molding journey—from initial part design through mold build, sampling, and production ramp-up.

- Part Design for Injection Molding (DFM)

- Mold Design & Engineering

- Tooling Vendor Management

- T1 Sampling & Qualification Support

Ready to Start Your Plastic Molding Project?

Contact Us NowEngineering Better Plastic Solutions

Our mission is to empower manufacturers with innovative, cost-effective, and high-performance plastic molding solutions that accelerate product launches and drive business growth. We strive to be more than a mold design vendor; we aim to be your trusted strategic partner in plastic part development, tooling engineering, and production optimization.

Advancing Plastic Molding Technology & Innovation

Promoting Sustainable Molding Practices & Recyclable Materials

Delivering Zero-Defect Tooling Solutions

Reducing Time-to-Market for New Products

Maximizing ROI Through Optimized Mold Design

Our Plastic Molding Process

A proven, transparent workflow designed to deliver production-ready injection molds efficiently—from initial concept to qualified tooling.

Part Design Review & DFM Analysis

We analyze your plastic part design for moldability, identifying potential issues like sink marks, warpage, undercuts, and draft angles. We provide a detailed DFM report with actionable recommendations.

Mold Flow Simulation

Using advanced simulation software, we optimize gate locations, predict fill patterns, analyze cooling efficiency, and identify potential defects before mold construction begins.

Mold Design & Engineering

Our engineers create comprehensive 3D mold designs including cavity/core, cooling channels, ejection systems, and runner layouts. All designs are reviewed and approved before release.

Tooling Fabrication & Build

We coordinate with certified mold makers to manufacture your injection mold using precision CNC machining, EDM, and wire cutting. Regular progress updates keep you informed.

Mold Trials & Qualification

We support T0, T1, and T2 sampling trials, analyze first-off parts, implement necessary modifications, and deliver qualified tooling ready for production.

Frequently Asked Questions

Everything you need to know about our services. Can’t find the answer you’re looking for? Feel free to contact us.

Get in Touch

Have questions or want to discuss a project? We love to hear from you. Fill out the form below and we ll get back to you within 24 hours.

Phone

+972598486982Monday - Saturday:8:00 AM to 6:00 PM

Sunday:Closed