Create production-perfect plastic parts with our comprehensive plastic injection molding design services. From initial concept through optimized mold design, we deliver engineering excellence that ensures manufacturability, reduces costs, eliminates defects, and accelerates your path from design to successful production.

Plastic Injection Molding Design Excellence

Optimized Designs for Perfect Production

We understand that successful plastic injection molding design requires more than CAD skills—it demands comprehensive knowledge of materials, processes, tooling, and production realities. Our integrated approach ensures every design we create is engineered for first-time-right molding, minimal cycle times, and consistent quality across millions of parts.

Whether you need plastic part design for a new product, mold design for production tooling, or DFM optimization of existing designs, our plastic injection molding design services provide the expertise you need. We guide you through every consideration—from wall thickness and draft angles to gate locations and cooling strategies.

Our dedicated design team leverages state-of-the-art CAD systems, advanced mold flow simulation, and decades of injection molding experience to deliver designs that exceed expectations. We don't just create drawings; we engineer complete plastic injection molding design solutions that ensure manufacturing success.

Expert Injection Molding Designers

Our plastic injection molding design team brings 20+ years of specialized experience, ensuring every design reflects deep understanding of molding processes, materials, and tooling requirements.

Advanced Mold Flow Simulation

We use Moldflow, Moldex3D, and SolidWorks Plastics to validate every plastic injection molding design, predicting and preventing defects before cutting steel.

Design for Manufacturability (DFM)

Every plastic injection molding design is optimized for production efficiency, reducing part costs by up to 30% through smart design decisions.

Complete Design Solutions

From initial plastic part design through detailed mold design, we provide end-to-end plastic injection molding design services under one roof.

Rapid Design Turnaround

Efficient design processes and experienced engineers enable fast turnaround on plastic injection molding design projects without sacrificing quality.

Production-Proven Results

Our plastic injection molding designs have been validated in production, with 98%+ first-shot success rates and minimal tooling modifications required.

השירותים שלנו

מחקר ופיתוח

הפיכת רעיונות לפתרונות פורצי דרך באמצעות מחקר מתקדם, אב-טיפוס ואופטימיזציה של תהליכים.

פיתוח מוצר

מרעיון למוצרים מוכנים לשוק, אנו מעצבים מוצרים פונקציונליים, אסתטיים ויעילים.

תבניות הזרקה

הנדסה מדויקת לחלקים מוזרקים באיכות גבוהה.

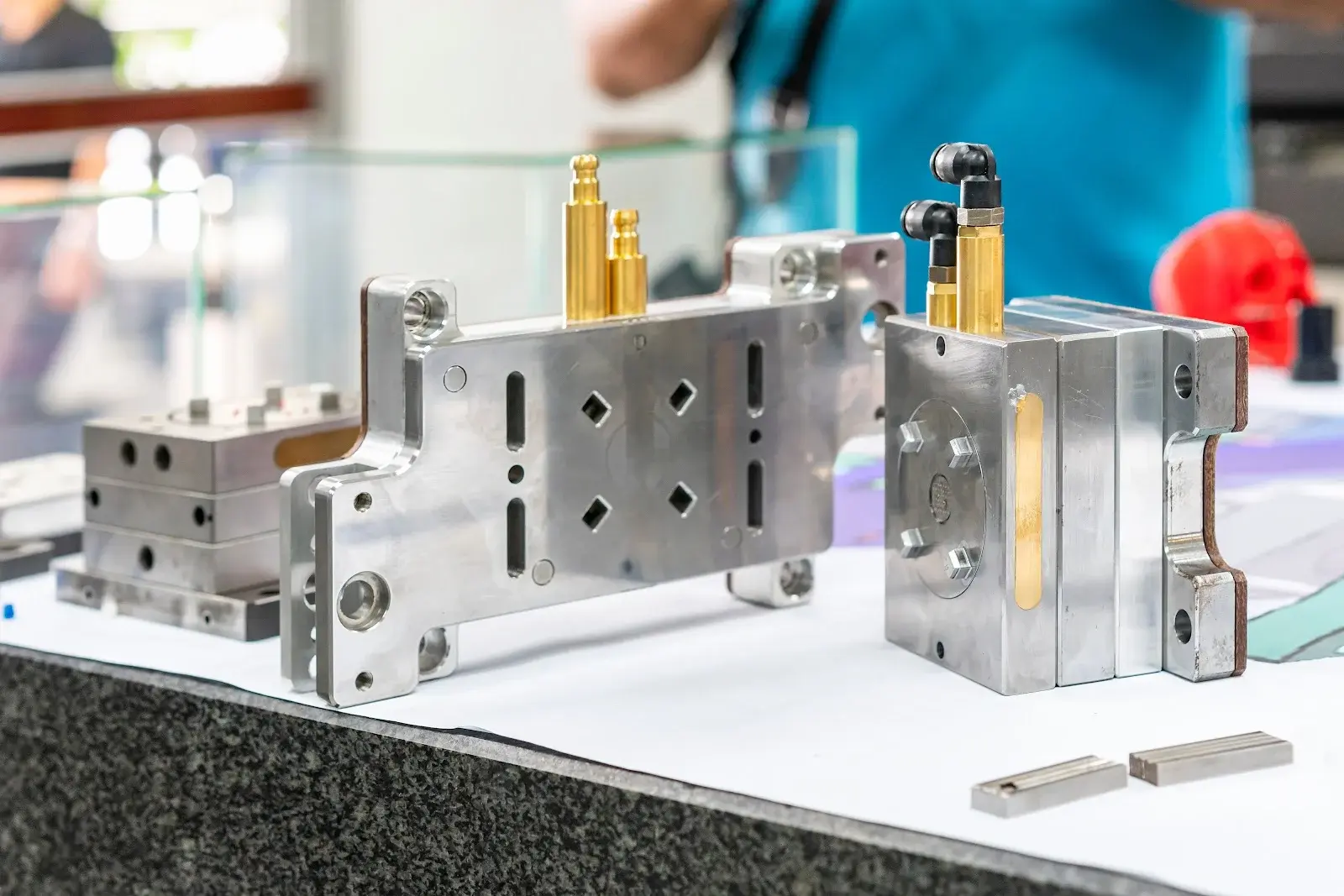

שירות CNC

שירותי עיבוד שבבי CNC בדיוק גבוה לחלקים מורכבים.

הדפסת תלת מימד

טכנולוגיית הדפסה תלת-ממדית מתקדמת לאב-טיפוס מהיר וייצור מותאם אישית.

השירותים שלנו

גלה את מגוון הפתרונות התעשייתיים שלנו

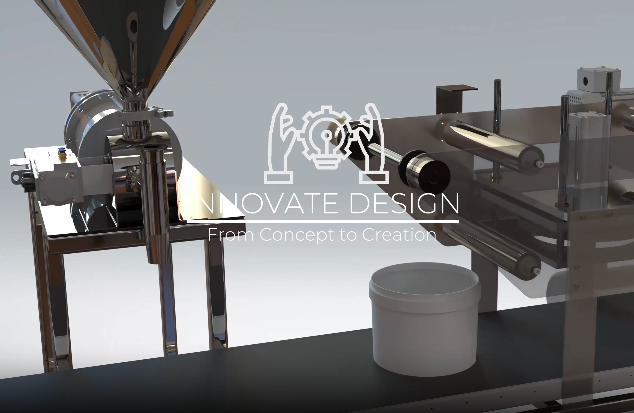

מכונת אריזה

פתרונות אריזה אוטומטיים מתקדמים לתעשיות שונות.

תבניות הזרקה

תבניות הזרקה מדויקות לייצור רכיבי פלסטיק.

חלקי חילוף

מלאי מקיף של חלקי חילוף מקוריים ותחליפיים.

מחקר ופיתוח

מחקר ופיתוח מתקדם לפתרונות תעשייתיים של הדור הבא.

Achievements

Why Choose Our Plastic Injection Molding Design Services?

We are committed to delivering plastic injection molding design solutions that ensure manufacturing success from the first shot. With 1,000+ successful mold designs and millions of parts in production, our expertise delivers results you can count on.

Design Expertise

Injection Molding Specialists

Our plastic injection molding design team specializes exclusively in injection molded parts and tooling, bringing focused expertise that generalist designers cannot match.

Simulation-Driven Design

Virtual Validation

Every plastic injection molding design is validated through advanced simulation before production, ensuring designs are optimized and problems are eliminated virtually.

- Mold Flow Analysis & Optimization

- Warpage & Shrinkage Prediction

- Cooling System Design & Validation

- Gate Location Optimization

Manufacturing Partnership

Design to Production

We support your plastic injection molding design through tooling, sampling, and production launch, ensuring designs translate perfectly into manufactured parts.

- Tooling Vendor Coordination

- First Article Support

- Production Troubleshooting

- Ongoing Design Optimization

Ready to Start Your Plastic Injection Molding Design Project?

Contact Us NowEngineering Perfect Plastic Injection Molding Designs

Our mission is to empower manufacturers with world-class plastic injection molding design services that eliminate production problems before they occur. We are committed to design excellence, continuous innovation, and building partnerships that help our clients succeed through superior injection molded products.

Delivering First-Time-Right Injection Molding Designs

Optimizing Designs for Cost and Quality

Eliminating Defects Through Simulation

Accelerating Time-to-Market

Building Long-Term Design Partnerships

Our Plastic Injection Molding Design Process

A proven, systematic workflow designed to deliver optimized plastic injection molding designs that ensure manufacturing success, minimize costs, and accelerate time-to-market.

Requirements & DFM Review

We begin by understanding your product requirements, reviewing existing designs for manufacturability, and providing comprehensive DFM recommendations to optimize your plastic injection molding design.

Plastic Part Design

Our engineers create or optimize 3D part designs with proper wall thickness, draft angles, ribs, bosses, and features specifically engineered for successful injection molding production.

Mold Flow Simulation

We validate plastic injection molding designs through advanced simulation, analyzing fill patterns, cooling, warpage, and potential defects to optimize designs before tooling begins.

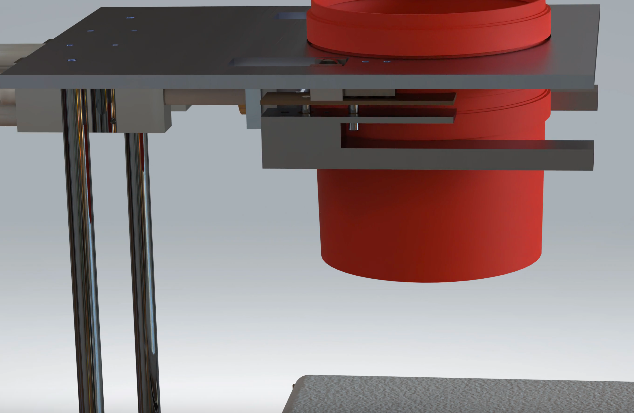

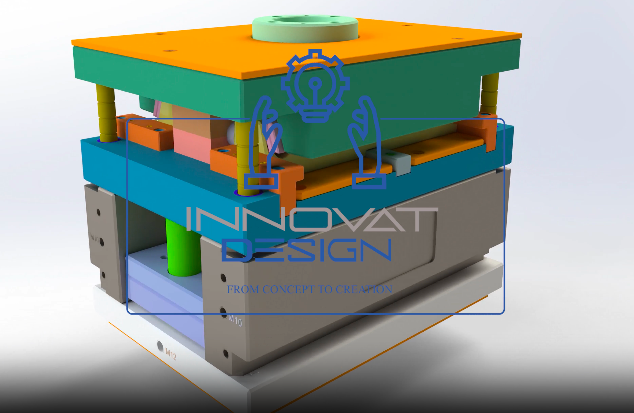

Mold Design Engineering

Our tooling engineers create detailed injection mold designs including cavity/core, runner systems, cooling channels, ejection mechanisms, and all components required for production.

Documentation & Support

We deliver complete design documentation and provide ongoing support through tooling fabrication, sampling, and production launch to ensure your plastic injection molding design succeeds.

Frequently Asked Questions

Everything you need to know about our services. Can’t find the answer you’re looking for? Feel free to contact us.

צור קשר

יש לך שאלות או רוצה לדבר על פרויקט? אנחנו אוהבים לשמוע ממך. מלא את הטופס למטה ונחזור אליך תוך 24 שעות.

דוא"ל

[email protected]טלפון

+972598486982ראשון - חמישי:8:00 עד 18:00

שישי:סגור